This weed control sprayer was brought in by a new client who complained the spray never worked the way she needed it to work. She bought a low cost power sprayer to save money and it shows.

When buying a pest control sprayer or weed control rig it is critical that you know what you are getting. When looking at this sprayer from a distance it may look ok. But close up or in the field, here are some problems to avoid:

1. Cheap plastic fittings won’t hold up to temperature extremes and variations. A cheap fitting can cause downtime or worse, chemical spills. (See the black plastic fittings on the right side of the photo).

2. The ball valve in the following photo is supposed to be used to shut off flow to filter so the filter can be checked and cleaned. The valve is so difficult to reach, the owner rarely checks it. This will lead to downtime and probably pump problems. Note also the cheap plastic fittings at the bottom of the tank. One turn on the ball valve can break a fitting and cause the tank to empty.

3. In the following photo the line from the tank to the filter is way too tight against the tank. The hose will vibrate. Which will leak first: the hose or the tank? Only time will tell. It is also more difficult for a technician to service without adequate slack or room to work.

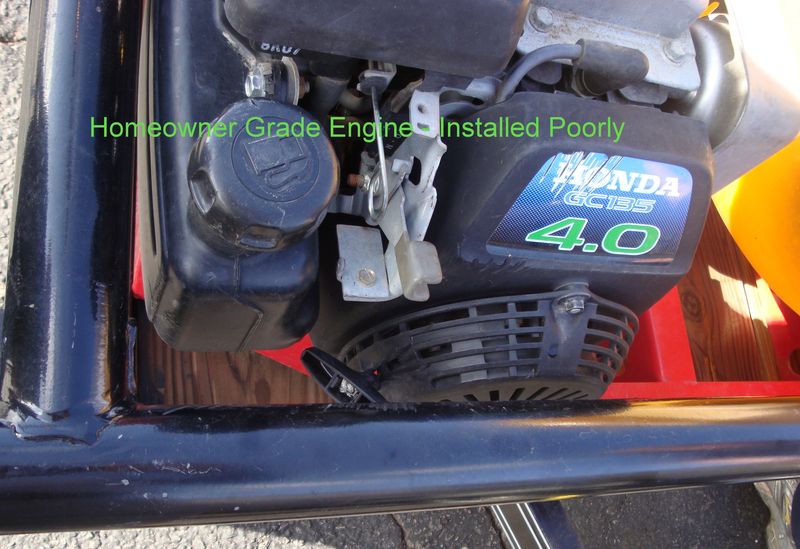

4. Engine. This is a consumer grade engine, not a commercial grade engine. For professionals, use the Honda GX commercial series of engines to stand up to the hard use. Also, engine is mounted too close to the side of the vehicle. Operator skins her knuckles every time she starts the engine. On a GX series engine, the recoil could have been rotated 90 degrees to mitigate this problem somewhat.

5. Client complained that she couldn’t agitate and spray the trees she needed to spray at the same time. The pump is too small to do both operations. When buying a power sprayer, be sure to take the time to explain to your equipment vendor how you will be using the sprayer so the correct spray pump can be installed.

Comments?